We’ve all been there. A red sock has found its way into a wash load of whites and now everything has turned a sickly shade of pink! Or you hang dark green towels on the washing line only to find that their lovely color fades in the sun. This is why it’s so important for manufacturers to ensure color fastness at the production stage.

If you’re researching textiles (or just looking to avoid laundry disasters) read this ultimate guide to color fastness of fabrics now!

What is Color Fastness?

Color fastness is the extent to which a fabric loses its color under certain conditions. Washing, exposure to sunlight, perspiration and daily wear and tear can all have an unwanted impact on colored fabrics.

Why is it Important to Know if My Fabric is Colorfast?

It’s important to know whether a fabric is colorfast for a number of reasons.

Firstly, so that fabrics of different colors (for instance, black and white) can be sewn together in the same garment without colors changing when the garment is washed.

Secondly, so that accurate washing instructions can be included on labels.

And thirdly, so that you know you’re providing a quality item to consumers. If colors run or ruin a garment, you’ll have lots of returns and lots of unhappy customers on your hands all of which will impact your brand image.

What Factors Affect Color Fastness?

So what makes some fabrics colorfast and others likely to ruin a wash load of clothes?

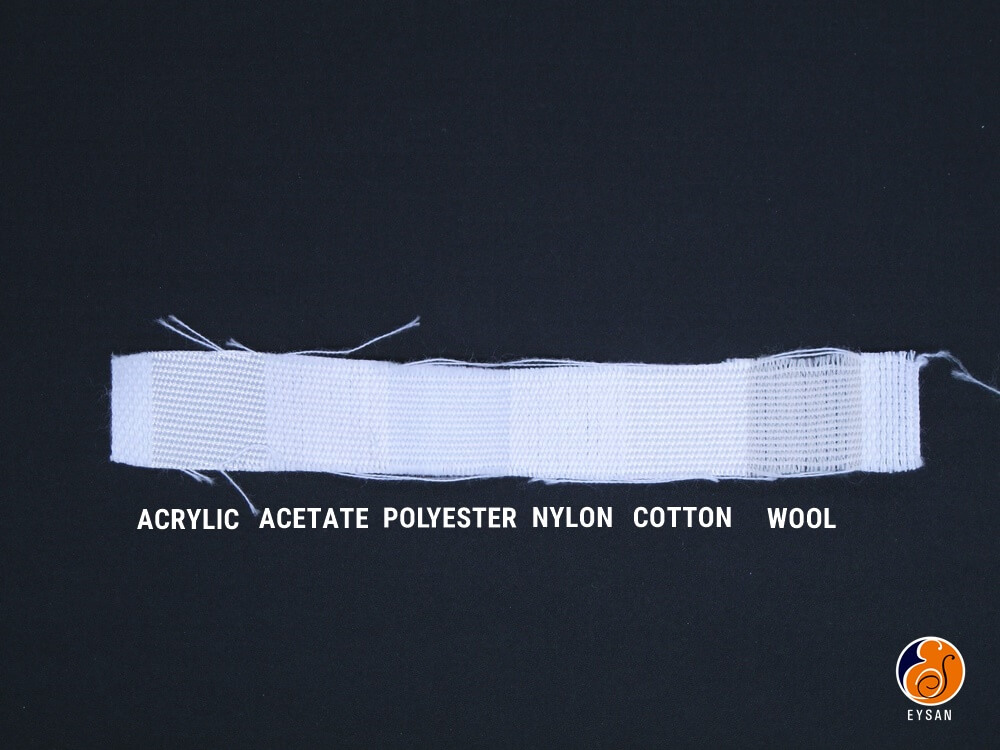

- Fiber. Each and every fiber has different properties. For instance, polyester is usually more colorfast than nylon.

- The color. Darker tones are less colorfast than lighter tones.

- The structure and characteristics of fabric dyes used.

- The properties of the fabric itself.

- Any fabric pre-treatments that have been used.

- Any damage to the fabric surface and any finishes that have been used.

- The dyeing process and whether fabrics have undergone soaping after dyeing.

- How a dyed fabric has been finished and fixed.

Which Test is Best for Telling Us if a Fabric is Colorfast?

Every fabric manufacturing brand has its own preference for the tests they choose to use in determining color fastness. But there are a number of international quality testing standards.

AATCC is the USA standard, ISO in Europe, JIS in Japan and CNS in Taiwan.

Whilst the tests have some differences, they all mimic the processes garments usually go through in the course of daily use.

The test fabric is then assessed for the level of fade. Or a strip of non-dyed, multi-fiber fabric is also included in the test and then assessed for the level of staining.

Color fastness is usually assessed at the lab-dip stage of production. So this is when a supplier will inform a buyer if fabric reach the required colorfast standards.

Most Commonly Used Colorfast Testing Standards

Here are some of the most commonly used colorfast testing standards, most suitable for assessing synthetic, knitted fabrics.

Color Fastness to Washing

ISO 105 C06 and AATCC61 are the most common standards for assessing how a colored fabric withstands washing at home.

Every testing method has specifications about the amount of water, washing powder or agent for washing and washing time. In addition, some testing standards will include small steel balls to simulate the friction of the cloths or other clothing accessories in the washing machine. For example, AATCC61-2A is a very common washing simulation test. It is a 45-minute test with 45 steel balls, which simulate the result of 5 five home laundries.

The fabric (along with a non-dyed fabric strip) is washed at various water temperatures in a machine specifically designed to test colorfastness to washing.

A fabric with good quality color fastness would achieve a color change rating of 4 and a color staining rating of 3 to 5.

However, a lot depends on the original color of the fabric. Not every color can reach these high ratings.

| Testing Method | Test no. | Sample Specimen Size (cm) | Water Ratio (ml) | Temperature (°C) | Wash Time (mins) |

|---|---|---|---|---|---|

| SO 105 C06 | A1S | 4x10 | 150 | 40 | 30 |

| A1M | 45 | ||||

| A2S | 30 | ||||

| B1S | 50 | 30 | |||

| B1M | 45 | ||||

| B2S | 30 | ||||

| AATCC 61 | 1A | 5x10 | 200 | 40 | 45 |

| 2A | 5x15 | 150 | 49 | 45 |

How colorfastness to wash is tested:

Color Fastness to Water

ISO 105 E01 and AATCC 107 are the most common standards for assessing whether a fabric color will run onto other fabrics while soaking in water.

How colorfastness to water is tested:

Color Fastness to Light

ISO 105 B02 and AATCC 16 Option 3 are the most common standards for assessing how a fabric reacts when exposed to sunlight.

Fabric is placed under a Xenon Arc Lamp, which mimics natural sunlight. In the case of AATCC 16 Option 3, a strip of fabric is placed in a fadometer and exposed to accelerated fading units (AFU) for 40 hours.

These tests are especially important for outerwear and for determining whether a garment can withstand everyday drying on a washing line in the sun.

How colorfastness to light is tested:

Color Fastness to Crocking (Rubbing)

AATCC 8 & ISO 105 X12 are the most common standards for assessing how colorfast a fabric is when continually rubbed against another.

For instance, if we wear a jacket over a t-shirt, after a long day of movement, will the fabric from one stain the other?

The tested fabric is rubbed against both wet and dry, non-dyed fabric for a specified time on a specially designed machine – a crockmeter.

Good quality materials score a rating of 4 for dry rubbing and 3 to 3.5 for wet rubbing.

How colorfastness to crocking (rubbing) is tested:

Color Fastness to Perspiration

ISO 105 E04 and AATCC 15 are the most common standards for assessing whether perspiration affects color fastness. It’s particularly relevant for fabric used to make sportswear.

Again a multi-fiber fabric is used along with the fabric being tested. AATCC 15 tests color fastness in the presence of acidic perspiration. ISO 105 E04 goes one step further and tests for color fastness in the presence of both acidic and alkaline perspiration.

Human sweat is typically acidic. But it can become alkaline in higher temperatures or when bacteria are present. So the ISO standard is the more thorough in this case.

How colorfastness to perspiration is tested:

Some Other Common Tests

- Color fastness to saliva. Especially important for baby and children’s wear and related products.

- Color fastness to chlorinated water. Especially important for swimwear.

- Color fastness to sea water. Again especially important for swimwear.

Where can Fabric Color Fastness be Tested?

Many fabric manufacturers will conduct in-house color fastness tests on their textiles.

But for a more impartial study, it is perhaps better to choose an international, third party laboratory. Examples include SGS, Bureau Veritas(BV) and Intertek.

How is Color Fastness Evaluated?

So tests have been conducted. Time to assess whether the color has faded or leaked onto your non-dyed fabric. But how to make an accurate evaluation?

Take a Look

Just taking a look at the fabric in question can help you to reach an assessment. But there are some drawbacks to this method.

If you have any level of color blindness or color deficiency, you might not be able to accurately judge what you are seeing.

And even if you don’t have any problems with your vision, the same fabric can look very different in different lighting conditions and under different light sources.

Use a Color Assessment Cabinet

To eliminate this issue, you need a Color Assessment Cabinet. This machine replicates different light sources in a consistent way, making your visual assessment of color much more accurate.

You put the tested fabric with the non-tested fabric, or the non-dyed swatch into the machine and set the appropriate light source. Some common light sources for color checking include:

- D65, which mimics daylight

- TL84 – the light most commonly used in shops in Europe, Japan and China

- U30 – the warm white light used in stores in the US

- CWF – the cool white light used in stores in the US

Under this light, you can then check your fabrics for color differences using the James Standard Heal Stained Grey Card.

The card will give you a rating from 1 to 5. The higher the number, the better the fabric’s color fastness.

How to Improve Color Fastness

Sometimes you might find that the fabric color you want to use isn’t as colorfast as it needs to be. In these cases, a color fixing agent can be used during the dyeing process to improve color fastness.

However, there are limitations. The color of your fabric has a big part to play. For example, light colors are more likely than dark colors to fade under bright light. And neon, bright and dark colors are more likely than light colors to cause staining.

If the fabric is made from regular polyester, it’s possible to improve the color fastness by changing the yarn to cationic polyester. However, cationic polyester can not improve the color fastness to light and the cost is higher.

Manufacturers need to consider these factors when deciding on garment design. It may be that they have to compromise a little on design in order to achieve the colorfast standards they’re looking for.

Conclusion

The level of color fastness you require and the tests you want to put your fabric through will all depend upon what your garments are going to be used for.

But it’s always a good idea to err on the side of caution. No customer wants their clothes ruined in the washing machine. Or looking drab and faded because they’ve been left to dry out in the sun.

In order to provide the best for your customers, only use fabric manufacturers and suppliers who ensure top quality color fastness.

So there you have it – the Ultimate Guide to Color Fastness in Fabrics. We hope you found it useful.

Check out our other articles below, answering all the most commonly asked questions about fabric purchase and production. Or get in touch today to find out about EYSAN’s extensive range of knitted fabrics.

Yarn, Piece or Solution Dyed Fabric?

Which dyeing method should you choose? Is yarn, piece or solution dyed fabric best for your product? Find out the key differences between these fabric dyeing methods.

What is Wicking Fabric? How Does it Work?

Sourcing material for outdoor or sports clothing? Chances are you’ve come across the phrase “wicking fabric“. But what is this stuff? How does it work?

Want to know more about EYSAN? Or looking for fabric advice?

Eysan Fabrics

Eysan is a knitted fabric expert. Since 1986, it has continually supplied quality fabrics and service to clothing manufacturers and well-known clothing, athletic, and underwear brands. If you have any questions regarding knitted fabrics or have any knitted fabric needs, please feel free to reach out to us.